Our plastic regranulates aren’t just on a par with new material in terms of quality – when it comes to their economic and ecological advantages, they are better than new. Because they save costs over the long term and reduce your company’s emissions. For decades, we have been refining our future concept for resource efficiency based on a rational closed-loop economy and have developed standards that are valid worldwide. This innovative strength continues to drive us forward. Together with our partners in the energenta group of companies, we are working every day on new solutions for our customers. With a clearly defined ambition: Nothing gets lost.

Our promise:

Sysplast optimises both your economic and CO2 balance sheets

With our compounds in new-material quality, we offer you not only a clear price advantage, but also the optimisation of your company’s ecological performance. Because Sysplast conserves valuable resources, returning them to your production cycles and sustainably lowering your CO2 footprint.

Our latest distinction:

Sysplast wins the 1st Bavarian Resource Efficiency Award!

We are thrilled and very proud. Bavaria’s environment minister, Thorsten Glauber, presents this special honour to Sysplast for our outstanding commitment to climate and resource protection. All about the award ceremony.

Our experience and competence:

Plastics recycling from waste electrical equipment. We developed it.

In the early 1990s, when we were still an internal business unit of Grundig AG, we began developing a recyclable housing material and an accompanying quality assurance system. Working under the name Sysplast – from ‘system’ and ‘thermoplast’ – we chose acrylonitrile butadiene styrene, as it was the most convincing engineering material from a combined economic and ecological perspective.

Our group of companies:

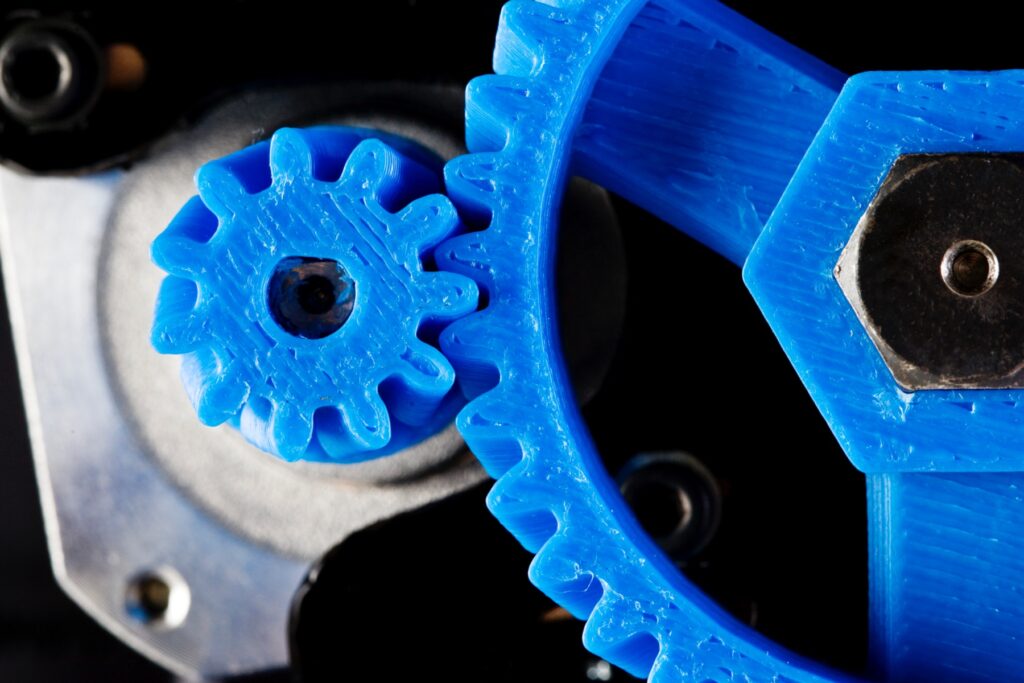

We separate metallised plastics by uniting competences.

In the energenta group of companies, we offer you all of the competences necessary for effective plastics recycling. In the plants of the Group companies, we demetallise galvanised plastic parts and separate composites into homogeneous materials, which we then grind down and reprocess into high-quality regranulates and compounds.